Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

Manufacturers often choose continuous vertical hoists because these machines seem to be some of them. Belt conveyor mobile products. The bucket-type, non-crushing hoist will accomplish these tasks. Then there will be major flaws. When discussing these options, let's take a closer look at why manufacturers use vertical hoists.

First, why choose bucket type without broken hoist

Belt conveyors are often used to drive their choice because the manufacturer chooses a continuous bucket-free crusher. However, belt conveyors are known to be poor in lifting products. They can only tilt 15 or 16 degrees before the product begins to roll down the belt. Therefore, when manufacturers must upgrade their products, they must use long conveyor belts that take up a lot of floor space (which is neither economical nor fast), or install some type of lifting equipment, such as bucket elevators.

There are two types of bucket-type crushless hoists: centrifugal and continuous. Centrifugal lifts are typically used to carry grain and other non-fragile materials weighing no more than 50 psi. On these lifts, the bucket will dig up a pile of grain and throw the grain onto the top of the lift.

The continuous bucket conveyor does not dig materials. The material is delivered to the bucket elevator and, under the force of gravity, enters the bucket that is normally attached to the belt. The bucket lifts the product and uses gravity to drain the product to the underside of the lift.

Second, the bucket type without broken hoist problem

1, maintenance

As mentioned above, there are many problems with bucket-type crush-free hoists. In short, they may be a nightmare for maintenance (and production). They are very complicated. They use motors that require maintenance. They increase energy costs. They increase the number of gears and parts to be tracked and replaced. They are difficult to clean, difficult to align and flow at the right speed, need to be tensioned and continue to run.

There are a lot of small problems that can go wrong. If you can't find them early, they can quickly cause big problems. Manufacturers using bucket-type, non-crushing hoists rely on plastic buckets that are bolted to the rubber bands. These bolts are subjected to large forces as the machine collects and lifts material. If these bolts fail and cannot be maintained in time, the bucket will tear the belt and cause a lot of damage and cause a lot of downtime.

2, chaos

Another minor issue is belt tracking. If the belt is slightly off track, the belt and bucket may begin to wear out. As the belt wears, it loses its integrity. They also cannot hold material due to the wear of the bucket. This can cause excess material to fall into the bottom of the bucket-free crusher, and the manufacturer must discard (past) or manually return the shovel to the system (wasting time).

Even without the use of a bucket, the elevator is messy. The accumulated material is formed below the conveyor belt of the elevator and the material is collected between the bucket and the belt portion.

Bucket-free, broken hoists are also difficult to prevent fires and explosions.

3, materials

Paper jam is one of the common problems with bucket-type break-free hoists. Mobile products may interlock or get stuck on the device frame, causing them to freeze. The production line must then be closed and the elevator opened and the jammed material removed before production can continue. Paper jams can also occur when material builds up in the bucket hoist or casing of the bucket hoist and blocks the machine.

Third, maintenance - easy and free

The good news is that customers know another option: our scraper conveyor. The trailer conveyor eliminates the problems associated with bucket-type, non-crushing hoists and can completely replace the belt conveyor system. First, the towed conveyor is easier to maintain than the bucketless, non-crushing hoist. They have fewer parts, no belts, no jams due to material build-up, no worn buckets to stop interlocking to start gripping frame parts, and no misunderstandings due to slippery or slippery belt drive systems ...

We even designed conveyors that are easy to maintain. Service technicians can change our curved wear strips from the outside and our heads are separate so that employees can easily use the three-piece independent sprocket. (The three-piece sprocket allows the maintenance team to change the sprocket without breaking the chain)

The conveyor has been in operation for many years and is only regularly maintained. Even in the corner, our wear strips rarely need to be replaced. Usually, all maintenance personnel must lubricate our conveyor belts.

Fourth, the building area

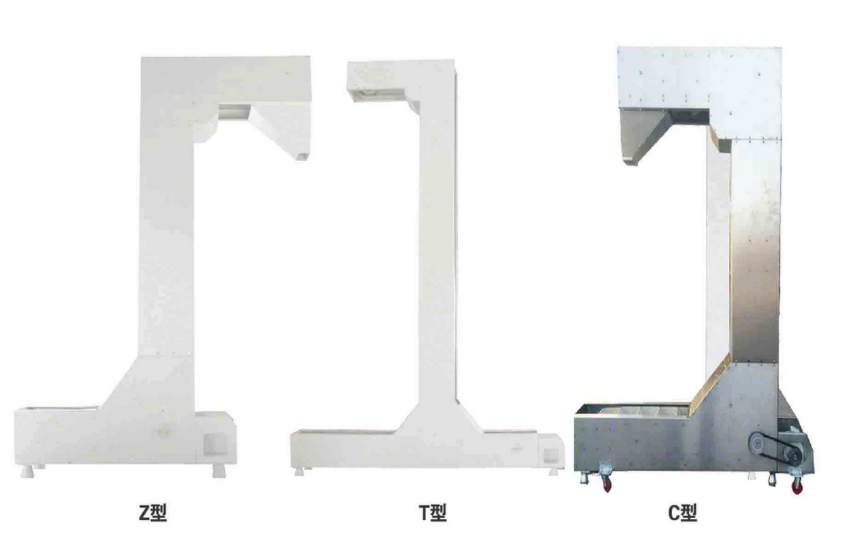

For our conveyors, raising material at steep angles is not a problem. The conveyor can raise the material to a vertical orientation at an angle not exceeding the small vertical angle of Z. This means it doesn't take up valuable space.

1, not messy

The tow conveyor also eliminates the hassles associated with bucket-type, non-crushing hoists. The floor or conveyor itself does not have any place to clean. In addition, because our conveyors are closed, they can be dust-proof. This eliminates debris in the air that workers must breathe, which makes the conveyor better from a safety point of view because it is easier to prevent and control fires.

2, gentle treatment

Drag the conveyor to handle the material gently. Our blades are designed with “fingers” that hold the product and prevent it from being packaged together so it runs smoothly in our machines and won't be crushed. This is no more rough than transferring material and pouring material. And unlike a screw conveyor/screw conveyor, it does not shred or break down material.

The material is also not affected by the rigorous grinding that continues in the conveyor chain. We use a double chain to pull the blades through our system, these blades are located on the conveyor side outside the material path. The towed conveyor is far superior to the bucket-type crusher without lifting the material.

The above is the content that Xiaobian shared for everyone. If you want to know more, please pay attention to the official website of Yongming Machinery.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such as copyright, portrait rights, intellectual property rights, etc., this website is not intentionally made and will be corrected immediately upon notification by the relevant right holder.

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机