Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

The circular vibrating screen is mainly composed of a sieve box, a screen mesh, a vibrator and a vibration-damping spring. The vibrator is mounted on the side plate of the screen box and is rotated by the motor through the V-belt to generate centrifugal inertial force, forcing the screen box to vibrate. If there is no special requirement, the circular vibrating screen is mainly divided into a textile screen surface and a punching screen surface, and all kinds of screen surfaces can be satisfied. Main components: 1, screen box 2, support seat 3, discharge hopper 4, feed hopper 5, screen 6, vibration exciter 7, flexible coupling 8, motor 9, motor seat.

Second, the characteristics of the circular vibrating screen:

1. The circular vibrating screen adopts the cylindrical eccentric shaft exciter and the partial block to adjust the amplitude, which is convenient to use and maintain;

2. The circular vibrating screen adopts spring steel woven mesh or punched sieve plate, which has long service life and is not easy to block holes;

3. The circular vibrating screen adopts rubber vibration isolation spring, which has long service life, low noise and stable over-resonance area.

The width of the screen surface is not only affected by the processing capacity of the screen, but also by the structural strength of the screen. The larger the width, the more certain the size of the screening machine is. The more problems that need to be solved in the structural strength of the screening machine, the more difficult it is, so the width of the screen surface cannot be arbitrarily increased. At present, the width of the vibrating screen in China is 3.6m; the width of the resonant screen is 4m.

The length of the screen surface affects the residence time of the screen material on the screen surface. The sieving test shows that when the sieving time is slightly increased, there are many particles smaller than the mesh, and a large amount of sifting through the mesh surface, so the screening efficiency increases rapidly. The test results show that the longer the sieve surface, the longer the material stays on the sieve surface, and the higher the screening efficiency.

However, as the sieving time increases, the number of sieving particles on the sieve surface becomes less and less, leaving most of the "diffuse granules", that is, the granules whose size size is close to the mesh size. The screening of these difficult-to-screen particles takes a long time, and the increase in screening efficiency is slower and slower. Therefore, the length of the screen surface is only within a certain range, which is effective for improving the screening efficiency, and the length of the screen surface cannot be excessively lengthened, otherwise the structure of the screen machine may be cumbersome and the expected effect is not achieved.

In general, the ratio of the length of the screen to the width is 2 to 3. For the screening of coarse-grained materials, the length of the sieve surface is 3.5~4m; for the screening of medium-fine-grain grade materials, the length of the sieve surface is 5~6m; for the dewatering and de-screening of materials, the length of the sieve surface is 6 ~7m; the pre-screened screen surface can be shorter, and the sieved screen surface should be longer.

Most of the series of width and length dimensions of screening machines in various countries use equal difference series. Its characteristics are: easy to use, the number of tails is relatively neat. However, due to the imbalance of the difference in the number of steps, as the number of columns increases, the relative difference will drop sharply. Therefore, in some series of screens, only two series tolerances can be used.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

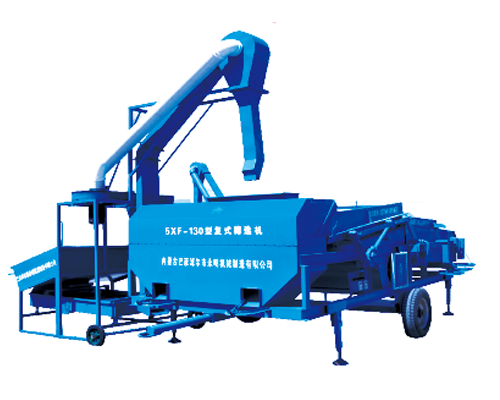

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机