Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

The maintenance of the bucket conveyor is a problem we often encounter. There are many things to pay attention to in the maintenance of the conveyor. The following are the safety precautions to be taken before repairing the bucket conveyor:

1. Please cut off the power of the fan before overhauling the bucket elevator. Tools used for maintenance must be safe and reliable, and maintenance personnel must wear safety helmets and safety belts for high-altitude operations.

2. When hoisting large objects, the hoisting signal should be designated, and the person in charge of the overhaul should give unified command. There must be no people or unused objects under the object, and the position of the object cannot be directly adjusted by hand.

3. Do not inspect and repair the electrical control system and motor of the lifting equipment when the power is on.

4. When using electric welding, prevent electric spark and arc radiation damage.

5. Except for maintenance personnel, no one is allowed to enter the maintenance site.

6. The overhaul standards and quality of all overhaul projects must be implemented in accordance with safety regulations.

7. During the test run, the person in charge of the overhaul should arrange an observer and stop the vehicle to find the problem in time.

8. Check the protective grid of the air inlet of the hoist, if it is damaged, please deal with it in time.

9. Detailed records of major repairs.

The above are the safety precautions to be taken before repairing the bucket conveyor. Safe production is no small matter. Regardless of the type of conveyor, its safety precautions must be strictly observed during the maintenance process so that the equipment can operate more safely. Thank you for your attention and support, see you next time!

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

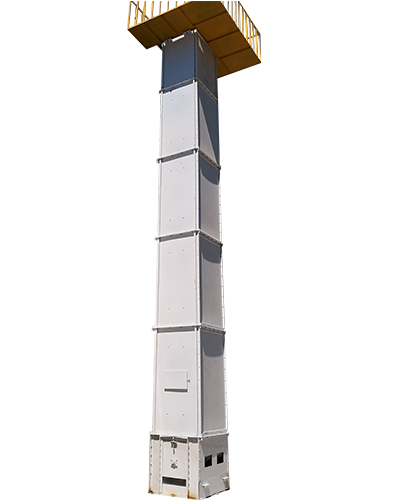

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机