Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

Product Details

Grain Impurity Screen: Commercial-Grade Grain Cleaning & Impurity Removal Equipment

1.Comprehensive Impurity Removal for Clean Materials

As a professional grain cleaning equipment, this Grain Impurity Screen excels in removing various impurities from seeds, wheat, nuts, corn, and other granular materials. It targets three types of impurities—light impurities (dust, chaff), coarse impurities (large wood pieces, strings, straw), and fine impurities (sand, broken grains)—ensuring high-purity processed materials and laying a solid foundation for subsequent production processes.

2.Advanced Screening Technology with Self-Cleaning Function

The equipment adopts a multi-stage cleaning design: light impurities and dust are first sucked out by a two-way gravity catcher, and the remaining materials enter a vibratory sieving trunk with two layers of sieves. The first sieve separates coarse impurities larger than grains, while the second sieve filters fine impurities smaller than grains. Built-in rubber balls realize automatic screen cleaning, preventing clogging, maintaining stable screening efficiency, and reducing manual maintenance costs.

3.High-Capacity Performance & Wide Industry Application

With a processing capacity of 2000-4000 kg/h for sunflower seeds, the Grain Impurity Screen supports continuous large-scale production. It is widely used in the agricultural product processing industry, suitable for cleaning various granular materials, and has become a preferred choice for grain processing enterprises due to its reliable cleaning effect and stable operation.

4.Seamless Line Integration & Eco-Friendly Design

Designed for assembly line compatibility, this equipment can be seamlessly integrated into automatic production lines. It works with cyclone dust collectors or pulse-jet bag filter dust collectors to effectively remove dust and protect the working environment. This integration not only improves overall production efficiency but also meets environmental protection requirements, creating a clean and safe workshop environment for enterprises.

1. Screen body

2. 0utlet of finished products

3. Vibrating sieve locker

4. Rubber shock absorber

5. Frame

6. Vibration part

7. Air screen inlet

8. Air screen dust outlet

9. Air screen outlet

Product Features

High production

Highly efficient grain cleaning

Occupied small area

Easy to adjust

Applicable to grading various materials

Minimal maintenance requirements thanks to optimized design

Flexible application possibilities via optional outlet aspirators

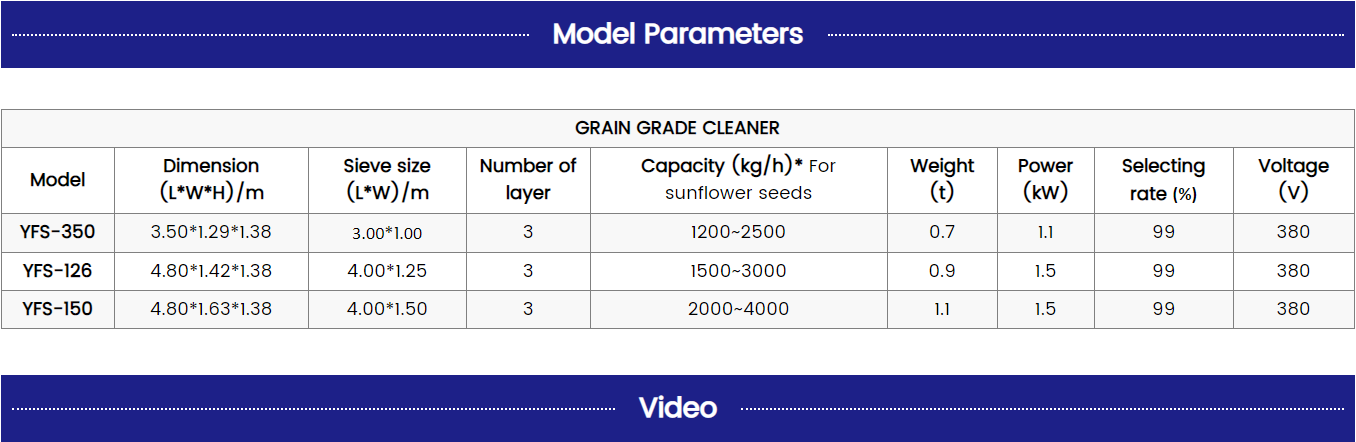

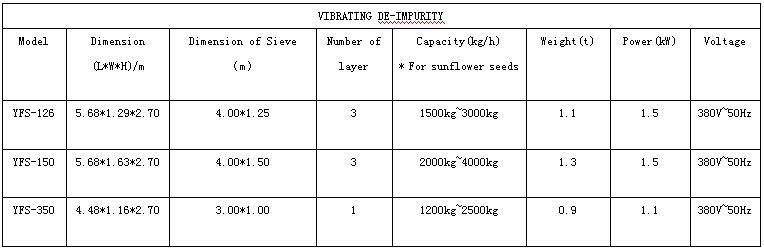

・ MODEL PARAMETERS:

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机