Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

Some large machinery and equipment will have instructions and precautions, and some small problems or failures will occur during the operation of the equipment. In fact, when minor problems or malfunctions occur, this is not terrible and can be dealt with in a timely manner. The following is a detailed introduction by the editor of the precautions for the use of the filter cartridge dust collector. The next article will introduce the troubleshooting methods for everyone:

Precautions when starting the filter cartridge dust collector:

1. This equipment has automatic start-stop function. When there is material transfer on the conveyor, it will open automatically, otherwise it will automatically disconnect the circuit and stop, so no special attention is required during operation.

2. Before starting, check whether the electrical control box is powered on.

3. When water is needed to reduce dust, check whether the valves on both sides of the solenoid valve in the water supply system are open, and whether the bypass valve is closed. It should be noted that the bypass bypass gate is a backup emergency valve. When the solenoid valve malfunctions, open it to reduce dust.

4. The filter should be cleaned frequently. The method is to open the drain door at the bottom of the filter when the filter is full of water. In this way, the dirt on the surface of the stainless steel core in the filter can be washed away to ensure the filtering effect.

5. After opening the filter element, pay attention to the running status of the dust collector. The electronic alarm box has a fault warning display. When the fan is running normally, the green indicator light is on. When the fan circuit temperature is too high, the red indicator light is on. At this time, the fan should be stopped and the fault should be operated only after the fault is found and eliminated.

6. When operating the filter dust collector, you should always observe the air volume and turbidity of the fan exhaust. When the filter bag and filter element in the dust collector are not damaged, the dust content at the discharge port is less than 50mg / m3, which is almost invisible to the naked eye. The wind is flowing. When the filter bag or cartridge is damaged, the dust content at the fan outlet will increase and the wind can be seen with the naked eye. At this time, the machine should be stopped and the filter bag or filter cartridge should be replaced to ensure the dust removal efficiency.

7. This equipment adopts pulse back blowing dust removal method to ensure the efficiency of the filter bag. The integrated control pulse controller is used to spray in separate rooms at regular intervals. Each injection frequency is 5 minutes, and the injection time is <0.2sec.

If an abnormality is found in the pulse system, such as frequent suction or non-operation of the pulse valve, please seek professional adjustment and repair. Non-professionals are strictly prohibited from adjusting the pulse controller.

8. The nominal pressure of the compressed air used in this equipment should be controlled between 0.18 ~ 0.2Mpa. When gas pipelines and valves are found to be leaking, the stop valve of the gas storage tank pipeline should be closed immediately, and it can be used after maintenance.

The above is the precautions shared by the editor about the cartridge dust collector, and the next part will introduce the troubleshooting methods in detail.

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

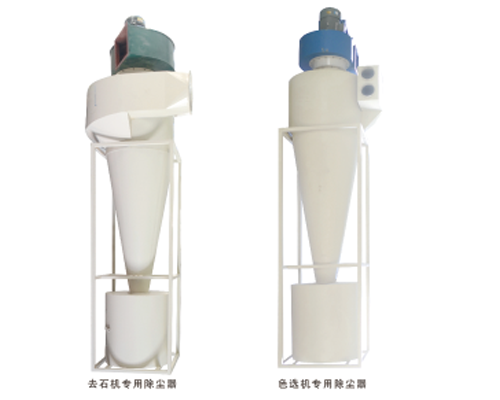

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机