Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

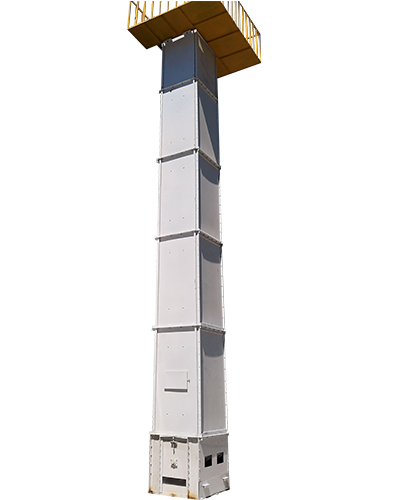

The vertical hoist is a mechanical device consisting of a lifting trough, a vibration motor, a vibration damping system and a base. It is mainly suitable for lifting from low to high. After the material is transported to the hopper through the vibrating table, the machine automatically runs upwards continuously. It is widely used for lifting and feeding food, medicine, chemical products, screws, nuts and other products. So, do you know how the vertical hoist works?

This series of bucket elevators uses a vibration motor as the vibration source. The centerlines of two identical types of vibration motors fixed to the lifting trough are angularly mounted and rotated in opposite directions. The eccentric block of the vibration motor reciprocates in a throwing direction by a part of the centrifugal force generated at each instantaneous position during the reciprocating motion, so that the entire body supported on the damper continuously vibrates, thereby causing the material to move upward during the throwing. After the chute is started, throw it away. At this point, the material can be in full contact with the air or it can be used for cooling. The hoist can transport powdered, bulk and short fibrous solid materials (except for viscous and easily agglomerated materials) and can also dry and cool the material. It is divided into two types: open and closed. Can be designed according to user needs.

1. Bond the material to the hopper and slippers, and regularly clean the mesh material according to the degree of bonding.

2. The loading hopper is not filled with the upper limit material.

3. The unloading chute is too small or the angle of the slippers is not suitable, and the slippers are modified.

4. The front part of the bucket elevator has insufficient mechanical structure and less animal feed. As a result, the gourd did not reach the predetermined experience, so there is a need to find a way to increase the labor capacity of the front machinery.

5. The size of the mechanical equipment at the rear of the hoist is small, the unloading chute is very crowded, and the production capacity of the rear mechanical equipment is improved.

6, the lifting speed is slow, you need to change the transmission ratio of the transmission wheel.

7. The hopper of the bucket elevator returns the material, that is, the material thrown by the hopper cannot enter the discharge pipe, but is partially returned to the machine seat, and the return is the end point of most hoist output.

Today's content is introduced here, we will release more relevant content on a regular basis, if you are interested, you can directly pay attention to our official website, thank you for your long-term support!

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such as copyright, portrait rights, intellectual property rights, etc., this website is not intentionally made and will be corrected immediately upon notification by the relevant right holder.

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机