Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

This article introduces some problems that may occur in bucket-type non-crushing hoist and provides possible solutions. Lifting bulk materials from one height to another, they are used in powders, granules, flake products and bulk materials. The following editors share content for everyone.

1 、 drive pulley

The drive pulley can be a top pulley or a bottom pulley. The motor and gearbox are driven by top pulleys, free of product spillage and dust. The belt tension need only be sufficient to provide sufficient friction between the belt and the pulley to lift the material.

Belt tracking and maintenance require an access platform for top drive of the elevator. With the bottom pulley drive, maintenance is easy, but the belt tension is doubled to provide the same drive friction. This increases the load on all moving parts. If the bottom drive wheel is coated with a product coating or the belt is stretched, the belt will slip. There are fewer operational problems with the top pulley drive.

2 、 The importance of cleanliness

When hoists are used in a variety of products, quick cleaning is required for the operator. The flange and bolt access doors are well sealed, but disassembly is slow and the threads may become dusty. Another option for harmless materials is to use

The bottom pulley should be self-cleaning and should not allow product to accumulate between the belt and the pulley. One method is to create a grizzly design using a round stick. Sticking rubber to the drive wheels increases driving friction. The rubber joint is cut at a 45-degree angle from the pulley shaft so that the joint gradually enters the friction area of the pulley.

3 、 Belt speed

Belt speed requires the material to be discharged from the bucket and into the discharge chute. The speed is too slow and the material slides from the tipped bucket over the top pulley and back to the bottom of the elevator. The speed was too fast, the material was thrown too fast, hit the top of the elevator, and then fell back to the bottom. This formula can be used to determine the correct belt speed and material throw.

4 、 Seal

The pulley bearing should be installed on the bracket outside the elevator cabinet as far as possible to prevent the shaft seal from leaking. Shaft seals should be designed to prevent leakage. Articles on protecting bearings in dusty environments can refer to some useful shaft sealing ideas.

5 、 feed tank

The product is fed into the elevator hood by passing the material through the chute under gravity or by a forced method (such as a power feeding screw). The angle of the feed chute and its cross section must be large enough to prevent product hanging or accumulation. Unblocked access is essential. Similarly, the angle, size, and design of the bins need to allow the product to flow freely.

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

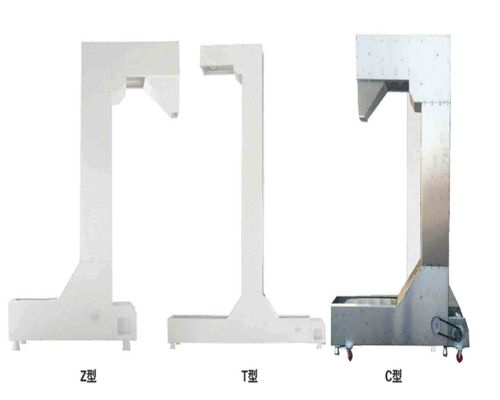

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机