Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

When it comes to the sorting machine, everyone will definitely emerge that the word should be "grain". Then this article will share with you the process layout skills of the cleaning machine equipment production line. Let's look down.

1. The layout of the cleaning machine equipment should be based on the total cost (H /). Under the premise of satisfying the normal operation of each device, the layout of the device should be determined according to the shape of the land purchased by the factory, which can be used as the road, yard and parking lot of the factory to facilitate the operation line of consumers. For the construction in stages, the installation space of equipment in each stage should be reserved in advance to facilitate the use of equipment in each stage in the future.

2. The equipment layout is compact. On the premise of meeting the needs of each equipment, the user line can be arranged compactly, saving the length of the auxiliary transportation equipment, not only wasting the sales cost of the equipment, but also increasing the power requirements of the equipment during operation.

3. The layout of the equipment should follow the principle of ease of use. There should be a wide enough channel between the equipment, the operator can walk around in the machine room, observe the operation of the equipment, and adjust the mandatory parameters of the equipment in time. If necessary, a platform and ladder should be installed around the equipment. When the seed variety changes, the operator can easily adjust the control buttons or handwheels on the equipment, and replace the essential parts such as the sieve plate and sieve cylinder in the equipment.

The number of pits of each plant should be reduced as much as possible, so as to facilitate the cleaning work when the plant type changes. For the equipment installed in high places, the corresponding maintenance platform or maintenance channel should be designed to facilitate the maintenance of the equipment before the end of the processing time (mainly including adding lubricating oil, grease, replacing worn and aging parts), and during the processing Medium and subsequent maintenance obligations (mainly reflecting the integrity of equipment, replacing wearing parts, etc.).

4. Arrangement of cleaning machine equipment control cabinet // h / The electrical control cabinet of each part should be arranged in the workshop to facilitate the passage and observation of the operation of the electrical circuit of the entire part, so that in an emergency, workers can enter Electrical control cabinet, and use the emergency stop switch to stop the entire part of the power cord to prevent accidents.

5. Safety protection measures during the operation of the cleaning machine equipment // h / If the height of the exposed operating parts is within the range of human contact, protective covers and other maintenance equipment should be made to prevent workers ’hair, clothing and other items Enter the machine to ensure operator safety.

Outdoor transportation equipment (such as outdoor belt conveyors) should be equipped with an outdoor emergency stop switch nearby, outdoor air equipment should be equipped with an emergency stop switch, and its location should be easy for workers to observe and touch, so that the operator can make emergency braking.

The above is the relevant introduction about the cleaning machine. For more information, please pay attention to the official website of Yongming Machinery.

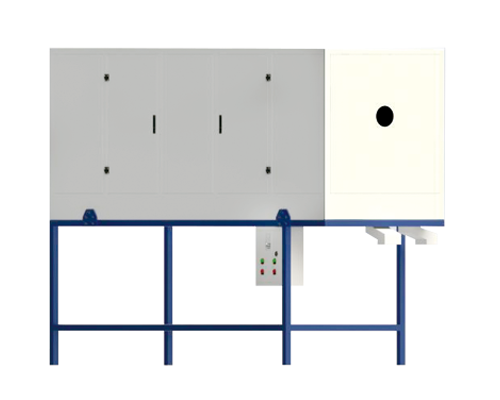

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机