Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

How to choose a hoist that meets the needs, it is necessary to understand its design method, it is very important to determine the design elements. There are many designs of elevators on the market, such as vertical bucket elevators, Z-type bucket elevators, etc. How to determine which design meets your needs, let us learn together.

"Bucket elevator design" is a broad term that can be divided into two parts: the design itself and the configuration of the equipment. "Design" in this article refers to a plan on how to build a hoist to meet specific application needs. On the other hand, "configuration" refers to how to arrange the feeding, vertical and unloading parts to adapt the equipment to the production process.

A. Design of hoist

Most hoists are designed for specific applications. Although many manufacturers will design for each model they provide, good manufacturers will tailor the design to each customer's application needs. In order to perform this custom design process, you need to understand the following:

1. The type of material to be promoted (ie powder, granules, flakes, etc.).

2. The characteristics of the material being promoted (ie bulk density, weight, water content, texture, size, etc.).

3. The particularity of the material being promoted (ie, whether it is free flowing, tacky, abrasive, explosive, toxic, etc.).

4. Expected throughput rate

5. Configuration and floor space that must be adapted

6. Upstream equipment that will feed the hoist and downstream equipment that will be unloaded

7. Operating conditions (ie continuous service and intermittent service, etc.) and environment (ie indoor / outdoor, high temperature / low temperature, etc.).

8. Any applicable regulatory requirements.

9. Special requirements (ie flushing service, etc.).

B. These basic inputs to the design process are essential to determine the final design elements, such as

1. The required elevator size

2. Whether open, closed or fully sealed design is required

3. Drive system and bucket to achieve the required throughput

4. The type of bucket used to successfully process the lifted material

5. Whether glidant is needed

6. How to design the feeding and unloading parts of the hoist so that it can be successfully integrated with upstream and downstream equipment.

7. How the design meets any operating conditions and environment, and any applicable regulatory requirements

8. How the design meets special requirements, such as flushing services.

C. About configuration

When designing an elevator suitable for a specific application, the designer needs to determine the configuration of the required equipment. Configuration is a key part of the elevator design process because the conveyor belt must fit the available space and be connected to upstream and downstream equipment. In many design projects, the position of the upstream and downstream equipment is fixed, and the designer must choose a configuration so that the feed and discharge parts of the hoist can reach and connect to the equipment.

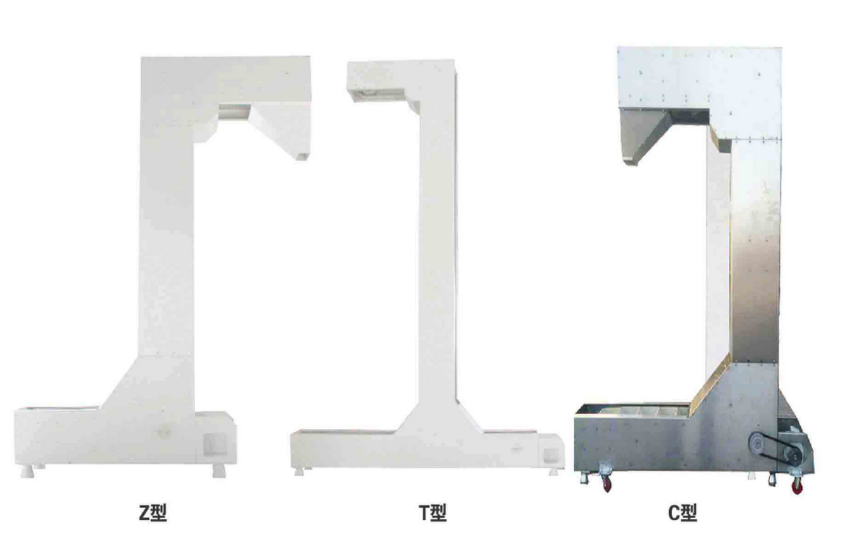

Commonly used hoists are equipped with standard "Z" type configuration, "C" type configuration, etc. The above is all the content that the editor has shared for everyone. If you have any needs or problems, new and old customers are welcome to call us and see you in the next issue. !

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机