Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

When designing the dust collector equipment, there will be problems in consideration of resistance. What is the resistance of the pulse dust collector equipment?

1. The main body of the pulse dust collector device generates a resistance when gas enters the dust collector outlet from the inlet of the dust collector.

2. When the gas passes through the bag of the dust collector, the dust collector bag will filter the dust in the gas, and then there will be corresponding resistance.

3. When the dust in the long-term filter gas of the dust collector bag will accumulate a layer of dust on the bag, if the gas passes through the bag of such a condition, the resistance will also occur, and the resistance at this time is far greater than the clean bag. The resistance of the time.

Sometimes the pulse dust collector equipment will run for a long time, which will increase the resistance of the dust collector equipment and will not achieve the original purification effect. If the resistance of the pulse dust removal device increases, how do you reduce the resistance? Hebei Kehan environmental protection equipment introduces you to three points:

1. Develop a reasonable filtering wind speed

The resistance of the bag filter is highly dependent on the filtration wind speed, and as the filtration wind speed increases, the resistance of the dust collector structure, the dust filter bag and the dust layer increases. Regardless of the filter material used in the pulse bag filter, the net filtration wind speed should not exceed 1 m / min. For the fine dust layer, since the dust particles are closely connected to each other, a lower filtering wind speed is required, otherwise the running resistance of the dust collector is greatly increased. However, many dust-removing equipment manufacturers must be more competitive in the market competition when selecting products. No matter how the other filtering wind speeds increase, the equipment cost can be reduced. The equipment resistance of such dust collectors must be higher than normal.

2, control the air flow speed

The rate of rise of the airflow refers to the flow rate of the flue gas in the space of the soot bag. The rate of rise of the airflow is an important parameter to measure the performance of the dust collector. It has a great influence on the performance of the low pressure pulse bag filter. Under the same air volume, the airflow rising speed is large, indicating that the distance between the dust bag and the bag is small in the effective bag space, the dust bag is compact, and the dust collector has a small shape, but the air flow rises. If the speed is too high, the running resistance of the dust collector will increase accordingly. Typically, the airflow rate is controlled at approximately 1 m/s to better utilize the performance of the precipitator.

3. Scientifically improve the cleaning effect

The dust layer on the surface of the dust collector has a great influence on the running resistance of the dust collector, so the cleaning effect is particularly important. There are many factors that affect the cleaning effect of the low pressure bag filter, such as the blowing pressure, the cleaning cycle, the length of the bag, and the distance between the bag and the bag. Without sufficient blowing pressure and energy, the dust layer on the surface of the dust bag cannot be completely removed. However, the blowing pressure should not be too large, otherwise the life of the dust bag will be greatly shortened. The injection pressure needs to be controlled within a reasonable range and needs to be flexibly adjusted according to the viscosity of the dust. The injection pressure should be controlled between 0.2 MPa and 0.4 MPa. From the point of view of reducing the running resistance of the dust collector, the surface of the dust bag is always in a clean state, and the resistance is small, and the dust bag needs to be dusted frequently, but at the expense of the life of the filter bag. Therefore, in the actual operation, we need to flexibly adjust the cleaning cycle according to the dust concentration in the flue gas and the viscosity of the dust.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such

De-impurity

Delivery of the wind for raw material

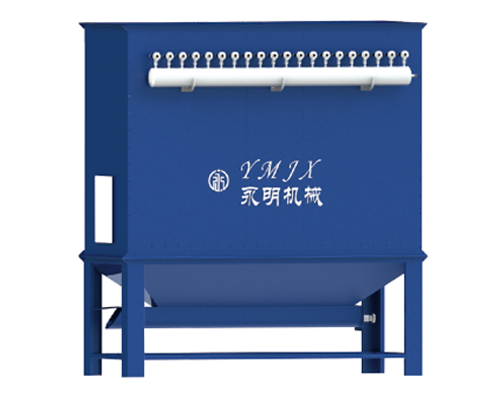

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机