Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

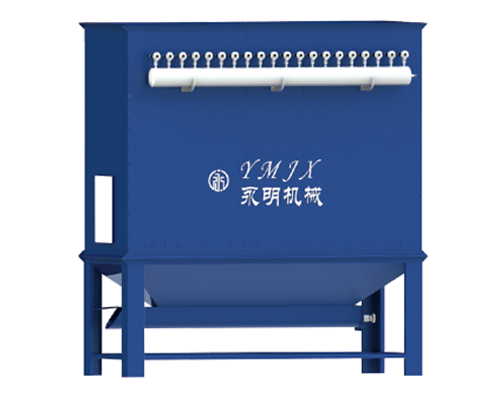

The pulse dust collector is a type of chamber structure assembly. The bag filter is used for the chamber filter bag, and the chamber air circulation box is pulse-cleaned through the chamber top pulse valve (so-called offline cleaning). It is different from the cleaning of conventional dust collectors. In the same filter chamber, only the filter bags of each row are sprayed and cleaned (so-called re-cleaning) and other filter bags are provided. Still filtering. That is to say, the cleaning and mixing are carried out simultaneously in one chamber, and the dust under the ash flies twice, and some of the dust is collected by the adjacent filter bags, which is not suitable for gas filtering dust concentration. The air box type pulse bag type dust collector is carried out under the condition that the indoor valve stops filtering, and the removed dust falls into half of the ash, and the secondary flight pulse type dust collector is not based on the bag type dust remover. The improved new high-efficiency pulse dust collector combines the advantages of sub-chamber back-blowing various pulse jet dust collectors, overcomes the shortcomings of insufficient chamber dust removal intensity, uneven distribution of inlet and outlet winds, and expands the application range.

The pulse dust collector refers to the sloping plate and the baffle that first hit the middle of the air inlet and the air outlet when the dust-containing gas enters the dust collector from the air inlet, the airflow enters the ash hopper, and the air enters the flow velocity decreases, and the coarse particles in the gas are Caused by inertia. Dust flows directly into the ash bucket. According to the pre-collected function, the airflow entering the ash bucket is then folded up and collected by the filter bag dust containing the metal skeleton inside, and collected on the outer surface of the filter bag, and the purified gas enters the clean room of the upper filter bag room, and is collect. When the tuyere is discharged and the dust-containing gas is purified through the filter bag, the dust accumulated on the filter bag increases with time, thereby increasing the resistance of the filter bag, resulting in a gradual decrease in the amount of process air, which is controlled for normal operation. The resistance is within a certain range (140--170 mm water column). Once out of range, the filter bag must be cleaned. After cleaning the dust, the pulse control device sequentially triggers each control valve to open the pulse valve. The compressed air in the air bag is blown out by the blow pipe. Each hole is sprayed into each of the respective filter bags through a venturi, and the filter bag is suddenly and rapidly expanded, thereby detaching the dust accumulated on the surface of the filter bag and returning the filter bag to the original state. Dust falls into the ash hopper and is discharged through the ash discharge system. Thereby, the dust accumulated on the filter bag is periodically pulsed and cleaned to allow the purge gas to pass normally, and the dust removal system is operated.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机