Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

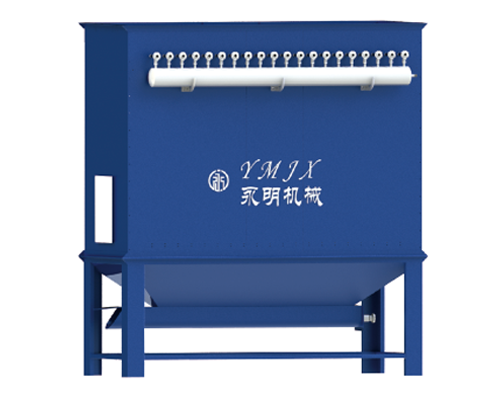

The bag pulse dust collector has been used for a long time, and its application area has reached 80%. In our country, it is widely used in ironworks, steel plants, ferroalloy plants, refractory plants, foundries, power plants and other places. The research is getting deeper and the cleaning effect is more and more obvious, and the dust in the flue gas is effectively removed. So what are the different characteristics of the pulse dust collector?

1. Processing method

Adopting the side air intake treatment form, the ash-containing flue gas enters from the side of the bag, and the filtered clean flue gas is discharged from the upper part of the dust collector. With this method, the system resistance is small, the dust will quickly fall into the ash hopper after cleaning, and the adsorption rate of the secondary dust is also very small. In addition, there is an airflow buffer and equalization device at the flue gas inlet, so that part of the coarse dust in the dust-containing flue gas settles and slides into the ash hopper after impact to prevent dust particles from directly entering, hitting the filter bag and damaging the dust removal The cloth bag, it has the function of a protective filter.

2. Operation method

With the online dust removal operation mode, the cloth bag can be cleaned separately without being isolated from the flue gas. The slowly rotating air pipe above the flower plate blows a large amount of air to the upper end of the cloth bag. The compressed air and normal smoke flow in the opposite direction, so the cloth bag is opened violently, which will shake off the dust on the cloth bag and make it fall into the ash hopper below. in.

3. Cleaning method

Combining the advantages of rotary back-blowing and pulse cleaning, the pulse rotary back-blowing cleaning method is adopted, so there is no need to set more pulse valves like that, which reduces the maintenance rate. Due to the pulse relationship, the dust cleaning method of the present invention avoids the disadvantage of large air consumption in the rotary back-blowing cleaning method, and the structure of the dust collector can be more concise without adding a reverse blower.

4. Application field

As emission standards become more and more stringent, the successful commissioning and use of bag filters in coal-fired power plants has made the advantages of dust removal equipment in terms of cost performance more prominent, and has become more and more important, and is favored by users.

The bag pulse dust collector is a product developed after years of accumulation of theory and practical experience and painstaking research. If you need it, please call us. Yongming Machinery will provide you with high-quality products and thoughtful services. We will next issue Goodbye!

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机