Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

The operation of the pulse dust collector is very important. When testing equipment, you can carefully ask the order of the equipment to start the equipment and the problems that need attention, especially the order of starting the power supply can not be reversed, to avoid the equipment not achieving the expected dust removal effect.

First, before starting the machine, check the preparation work to do a good job, look at the links of the various parts of the equipment, and whether there is a leak or gas leak before starting.

Second, this is an important point. The continuous start of the pulse dust collector cannot be performed twice. If the green light goes out after 15 seconds of starting, check the power supply unit for malfunction and perform pulse dust removal. Clean up the work.

3. In the ventilation fan part of the pulse dust collector, the poppet valve and the bypass valve must be tested and perfected before the induced draft fan is opened. When the above components are closed, one of them needs to be opened to prevent the fan from opening, thereby damaging the device.

4. When the control device of the pulse dust collector is powered on and prompted, the digital tube will display the corresponding number. The pulse interval and pulse width potentiometer should be adjusted accordingly. When adjusting, pay attention to the clockwise direction, the interval and the width increase time, so that the pulse dust collector is kept in good working condition.

5. After the pulse dust collector is completed, check the filter bag section. If it is damaged, please consider replacing it and clean the dust on the filter bag in time. The dust in the bucket should also be disposed of. Also check the tightness of each component for better use next time.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such

De-impurity

Delivery of the wind for raw material

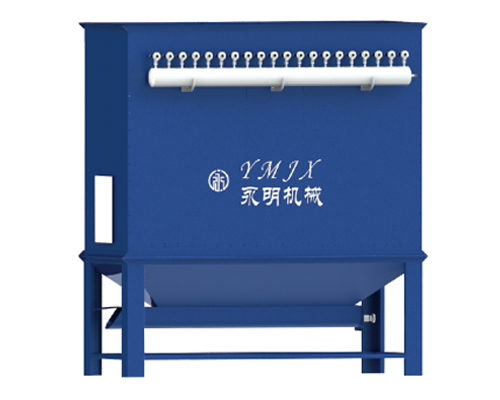

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机