Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

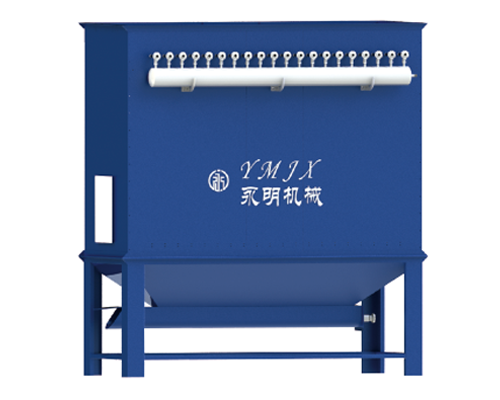

In order to improve the dust removal efficiency, we now have a new type of pulse dust collector, which is cleaner than the traditional traditional pulse dust collector, with lower dust removal capacity and emission concentration. Of course, it can also achieve obvious energy-saving effects, and can maintain good economic benefits for a long time.

Due to the small size of the pulse dust collector, the installation area can be greatly saved during use and installation, and the use efficiency can be improved. The key is that it can improve the dust removal effect. It is widely used in various metallurgical industries for air purification or recovery of useful materials. After all, it uses the split-room downwind pulse soot blowing technology, which can achieve the purpose of dust removal at one time, so it has a good appearance in soot blowing and dust collection. Extending the cleaning time in the blow molding process can greatly reduce the energy loss during the cleaning process, so the energy saving advantage is more prominent.

Of course, the pulse dust collector adopts good partition dust removal technology. At this time, the bag can be overhauled or replaced without stopping the fan, so the efficiency advantage will be obvious. The dust removal effect is significantly improved. Of course, in order to be guaranteed, we need to carry out more reasonable treatment at this time, otherwise it will cause energy loss. In view of this, we know from the above that the advantages of the dust collector are very obvious, not only saving energy, but also greatly improving the effect of dust removal and dust removal.

5 correct installation steps of pulse dust collector:

1. When lifting the pulse dust collector, pay attention to prevent deformation. When the equipment leaves the factory, the key components are all welded with lifting lugs. Please use lifting lugs for lifting.

2. After installing the pulse dust box, dust chamber, air inlet and outlet, ash hopper, etc., all connections should be airtight and airtight. If welding and sealing are required, air-tight welding should be performed. If fasteners are used for connection, washers should be added and all fasteners should be tightened. For local air leakage, please use silicone or epoxy to prevent rain. The sealing quality of the pulse dust collector is an important factor affecting the normal operation and life. The dust collector requires an air leakage rate of less than 3%.

3. When assembling the air circuit components, the main air pipe has been separately manufactured in the factory. As long as it is assembled on site, the control air pipe (connected to the lift cylinder) should be installed on site, such as material cutting and snapping. If there is debris, all joints should be filled with sealing material, and no air leaks after the pressure test.

4. Installation of the bag cage and filter bag is a careful work in all installations, so it should be done after installation. During installation, the filter bag must not collide with hard objects or scratches even with small scratches. Will greatly shorten the service life of the dust filter bag. The method of installing the filter bag is to first put the dust bag from the flower plate hole of the box body into the bag room, then pinch the spring ring on the top of the bag mouth into a concave shape, put it into the flower hole plate of the box body, and then restore Spring ring. Press it tightly on the circumference of the flower hole, and then gently insert the bag cage from the mouth of the bag until the lid on the upper part of the bag cage really presses on the flower plate hole on the box. In order to prevent the filter bag from being stepped on, it is necessary to install the dust removal frame, filter bag, dust bag cage and flower hole plate every time the filter bag is installed.

5. After installing the bag cage for the air box pulse bag filter of the coal mill, the pressure plate must be installed to make the ground wire on the filter bag, the bag cage and the flower plate close contact. The explosion-proof door on the gas box pulse bag dust collector of the coal mill has been adjusted before leaving the factory, and there is no need to adjust it again during the installation process.

The above is about the correct installation steps of the pulse dust collector. I hope that what I shared above can help everyone. Thank you for your attention and support. If you want to know more, please pay attention to the official website of Yongming Machinery. See you next time!

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机