Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

Application Fields and Applications of Pulse Dust Collectors Currently, pulse dust collectors are faced with various dust characteristics and changing production processes, and their application fields are gradually expanding. There are many reasons for this, and it plays a vital role in dust removal technology. Progress has enabled our manufacturers to prevent and other equipment parameter design, model selection, and various unfavorable factors (high temperature, high humidity, high dust concentration, fine dust, moisture absorption dust, corrosion, flammability, large fluctuations in working conditions, etc.) The aspects are very good.

At the same time, the cleaning mechanism of the pulse dust collector is continuously deepened. A clear definition of dust collection in a dust bag is that the decisive factor is the pressure peak and pressure rise in the bag during cleaning. The speed and reverse acceleration of the bag wall can be obtained. We should not mistake it for dust removal time or air volume.

The root cause of excessive dust emissions

1. The initial layer of the filter bag surface is insufficient;

2. The filter bag is damaged;

3. The filter bag is poorly assembled;

In the operation of the precipitator, if the discharge exceeds the standard and the operating pressure of the precipitator is lower than the design, the initial powder layer on the surface of the filter bag is likely to be insufficient. The reason may be that the filtration rate of the filter bag is too high and the filter bag is too high. The cleaning cycle is too short, the pressure of the compressed air is too high, and the load of dust is reduced.

Studies have shown that: the filtration speed is too fast, the dust discharge rate will increase, and the excessively high filtration gas speed will cause the initial dust layer to rupture. If the filter bag is too high, the dust will impact the filter bag and cause excessive wear. Loose, causing the dust collector to be excessively discharged.

When setting the pulse cleaning time of the precipitator, it is ensured that the precipitator operates under a stable pressure and the set pulse cleaning cycle time is long. The pulse cleaning time ensures that the initial dust does not fall off and sets the set time. Cleaning is shorter. If the initial dust layer is insufficient, you can supplement it with an extended cleaning cycle. If differential pressure control is used, the stability of the inlet and outlet pressure settings of the dust collector can be improved.

If the discharge of the precipitator exceeds only after cleaning the filter bag, it is only necessary to check if the pressure of the pulsed compressed air is too large.

The reduction in dust load may be due to reduced productivity or maintenance and adjustment of the dust collector control system. Solution: It can be solved by light load or slow start of the load with pre-dust.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such

De-impurity

Delivery of the wind for raw material

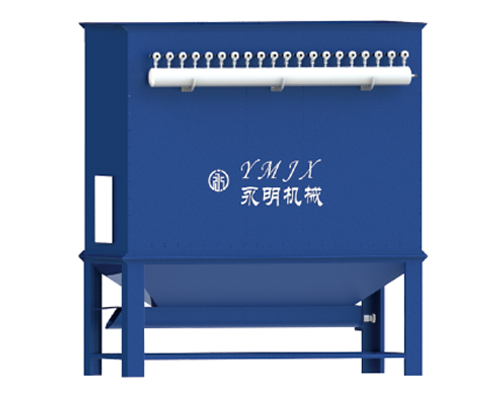

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机