Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

I. Overview

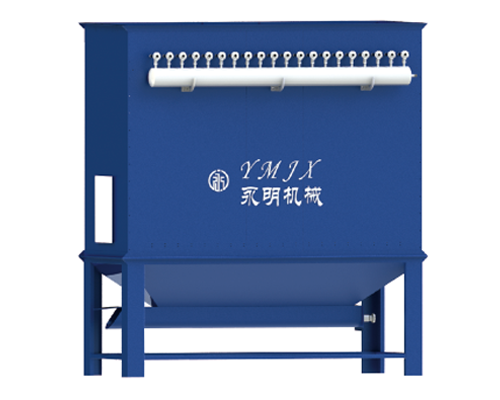

DMC single-pulse dust collector is a small bag type dust collector designed by our company to digest and absorb the advanced technology of similar foreign products. The dust collector adopts high-pressure (0.5~0.7MPa) large-flow pulse valve to spray the cleaning filter one by one. Compared with other single machines in China, it has the characteristics of large cleaning function and high cleaning efficiency. The utility model has the advantages of small volume, light weight, simple and compact structure, easy installation and convenient maintenance (external filter type), and is widely used for purifying dust-containing gas in industries such as building materials, metallurgy, mining, chemical industry, coal, non-metallic minerals and ultrafine powder processing. The treatment system is the ideal equipment for environmental dust removal.

Second, the structure and working principle

1. Single machine pulse dust collector structure

The device mainly consists of the following components:

(1) Box: including bag room, clean air chamber, perforated plate, filter bag, filter bag skeleton, access door, and box design pressure resistance is 5000Pa.

(2) Air outlet system: including fans and fans.

(3) Injection system: including main air pipe, blow pipe, pulse valve, and control instrument.

(4) The ash discharge part of the intake air has two forms: one is a standard ash bucket type, and the other is an open flange type.

2, working principle

The dust-containing gas enters the ash hopper from the air inlet or enters the filter bag chamber through the open flanged port. The dust-containing gas is filtered through the filter bag to be cleaned into the clean air chamber, and then exhausted through the clean air chamber. go. The dust accumulates on the outer surface of the filter bag and increases continuously, so that the resistance of the bag filter is continuously increased. In order to prevent the resistance of the device from exceeding 1200 Pa, the bag filter can continue to work, and the dust on the filter bag needs to be periodically removed. The cleaning is started by the program control timing sequence to start the pulse valve, so that the compressed air (0.5~0.7MPa) in the air bag is ejected from the orifice of the blowing pipe (called the primary wind) and induces several times the ambient air of the primary air through the venturi. The secondary air enters the filter bag to make the filter bag expand rapidly in an instant, and shakes off the dust with the vibration of the airflow to achieve the purpose of cleaning.

Third, the selection

1, model description

The single machine has six common specifications of 32, 48, 64, 80, 96, and 112. It can also manufacture special specifications according to customer requirements. Each of the specifications is divided into two installation forms to meet the requirements of different occasions.

2, selection parameters and selection principles

(1) The main technical parameters of the dust collector selection are air volume, gas temperature, dust concentration and humidity. According to the process design, the higher values of air volume, gas temperature and dust concentration are based on the values in the technical performance table. The corresponding dust collector model is the required dust collector model.

(2) The air consumption in the table is the case when the factory supplies air in a centralized manner. If the air compressor is used alone, the air consumption in the table is enlarged to 1.5 times.

(3) In the compressed air consumption column, the proposed air consumption is the larger air consumption of the model.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机