Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

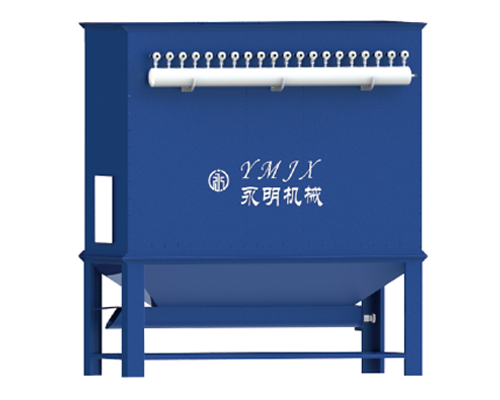

The following small series should introduce you to a basic operation of the DMC pulse dust collector. If you are not very skilled, you can follow the small series to learn the correct one.

1. When the dust is filtered through the dust filter bag, part of the dust remains on the outer surface of the filter bag to form a gray cake layer. When the filter dust reaches a certain thickness or a certain time, the running resistance of the bag filter will increase, so that the resistance is controlled. Within the limited range (generally 120~150mmH2O), the dust collector is equipped with a differential pressure transmitter (or pressure control instrument) or a time relay to detect the pressure difference between the dust chamber and the clean air chamber.

2. When the pressure difference reaches the set value, send a signal to the pulse controller, and the pulse controller sends a command to trigger the pulse valve to be turned on in order, so that the compressed air in the air bag is sprayed from each hole of the spray pipe to each corresponding filter. The bag causes the dust bag to expand rapidly in an instant.

3. Under the action of the negative pressure airflow, the dust-containing gas quickly enters the dust-removing body from the inlet of the separator, and the dust is separated from the airflow through the filter bag filtering action, and the purified clean gas enters the clean air chamber from the inside of the filter bag. Discharge, so that you can achieve the effect of dust removal, a process in which dust is filtered.

4. When the bag filter is in maintenance, first cut off the power supply, the operator must carry the key of the operation panel, and hang the "under repair, no operation" sign on the operation panel.

5. During daily inspection or operation, when the fault is temporarily handled, the operator must strictly prevent the clothes from being twisted into the transmission. When entering the ash ash cleaning or entering the bag room bag, you must wear labor protection equipment to prevent dust from getting into the eyes or burn your skin.

6. When the differential pressure transmitter exceeds the low limit setting value, the differential pressure transmitter sends a signal to indicate that the dust filter bag is damaged. At this time, stop the machine and check the repair.

7. Frequent cleaning of dust collection or other deposits on the high voltage network to ensure insulation performance. The grounding resistance is checked once a year to ensure that its resistance is within the allowable range.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机