Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

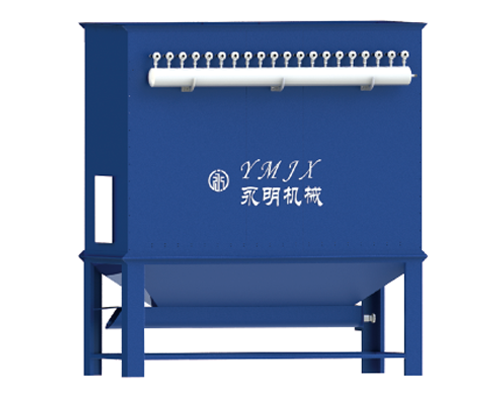

Yongming Machinery Xiaobian takes everyone to know the steps of using the pulse dust collector. Before the DMC pulse bag filter is turned on, the whole system should be thoroughly inspected, and the solid debris brought in should be removed to check whether there is any air leakage or tight sealing. If it should be handled in time. Procedures for the operation of the pulse bag filter in use:

First, the preparation of the dust removal system before starting:

1. Before the dust collector is turned on, it is necessary to carry out a comprehensive inspection of the whole system to remove the solid debris brought in, and check whether there is any air leakage or tight sealing. If it is necessary, it should be disposed of in time.

2. Check that all transmission parts are filled with lubricant and function well.

3. Use clean compressed air or nitrogen to periodically check the water in the exhaust gas storage bag (check every 15 days).

Second, the booting sequence of the dust removal system is arranged in 1~4

1. Start the compressed air source to inflate the air bag.

2. Open the electric control cabinet blowing system.

3. Start the dust extraction system induced draft fan.

4. Adjust the control panel of the controller to determine the cleaning time interval (ie: cleaning cycle) according to the amount of dust.

Third, the dust removal system shutdown sequence is operated in 1~4 arrangement.

1. Turn off the power of the induced draft fan first.

2. Turn off the power of the cleaning program.

3. Turn off the air supply.

4. Turn off the main power supply.

Fourth, note:

1. Dust removal equipment should be operated and repaired by special personnel. Fully master the performance and structure of the dust collector, find problems and deal with them in time to ensure the normal operation of the dust removal system.

2. Under normal circumstances, the dust removal system should be driven before the production process equipment, and then the dust removal system should be shut down after the production process equipment is stopped for 5~10 minutes to avoid dust deposition in the dust removal equipment and pipeline, or run due to the dust removal system. In order to prevent the overload of the motor, it is necessary to start the induced draft fan at a low air volume (the damper is closed).

3. If the dust removal equipment is used under high temperature conditions, the flue gas should be discharged by bypass pipe when the process equipment is ignited. After the temperature is normal, it will enter the dust removal system for dust collection.

4, often check the cleaning mechanism, and the working conditions of the rotating parts, should be regularly oiled or necessary maintenance.

5. If the dust concentration of the discharge port increases, it indicates that the filter bag has been leaked, and the filter bag should be replaced in time. When replacing, first stop the fan and then open the access door on the upper part of the dust collector. If there is dust on the filter bag mouth, the filter bag is damaged and must be replaced or repaired.

6. The cleaning pressure of compressed air should be controlled within 0.4MPa~0.6MPa, generally 0.4MPa. The filter of the compressed air system should be drained regularly, and the drain valve of the air bag should be drained regularly.

7. The cylinders on the electromagnetic pulse valve and the temperature control valve should be inspected by professionals, and the electromagnetic pulse valve and the solenoid valve of the cylinder should be inspected regularly.

The above is a detailed introduction to the detailed operation of the DMC pulse dust collector and the matters that should be paid attention to during the use. Have you learned it? If you are interested in purchasing related equipment, you can call Yongming Machinery to learn more.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机