Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

Hello everyone, Yongming Xiaobian wants to introduce the structure of its products to everyone, what is it like, look down together.

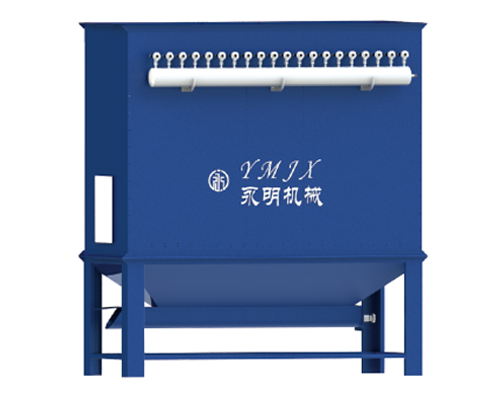

DMC type pulse bag filter unique structure

1) DMC type pulse bag filter is a modular production unit combined dust removal unit. The filter area of each unit can be adjusted according to actual needs, and the number of units can be changed to adapt to the required filtered air volume.

2) The DMC type pulse bag filter is an external filter type dust collector, that is, the dust-containing gas is outside the filter bag, the clean air is in the filter bag, and the bag mouth is upward. The cleaning function uses the timing and manual functions to control the start pulse injection valve to blow, so that the filter bag is radially deformed and the dust is mixed. The dust collector also has an offline maintenance function.

3) DMC type pulse bag filter adopts the design concept of high air volume and low wind speed. The actual filter wind speed of the dust collector is 1.6m/min. Before the equipment leaves the factory, the main part of the injection system is pre-assembled to ensure the quality.

4) The dust collector plate adopts the numerical control stamping method to process the flower plate hole, which ensures the geometrical tolerance requirements of the flower plate and the flower plate hole.

5) The secondary distribution method of airflow is adopted to allow the dust-containing airflow to enter the filtering zone through the diversion pipe and the air distribution system, thereby ensuring the uniformity and smoothness of the unit air inlet, so as to improve the filtration area utilization rate and the filter material service life.

6) The upper end of the filter bag adopts the form of spring rising ring, which has good sealing performance and quick change of bag. Only 1-2 people can change the bag through the top of the top.

7) The bag cage adopts a round type (8 ribs) structure, and the top roller is equipped with a “η”-shaped cold-punching short pipe to ensure the verticality of the bag cage and the safety of the filter bag mouth when blowing. The bag cage is made of carbon steel and the surface is galvanized. The corrosion of the cage bone surface and the filter bag are prevented after the dust collector is operated for a period of time, which ensures the smooth change of the bag and reduces the damage to the bag during the bag changing process.

8) The dust collector adopts a sticky top cover. The design of each top facility adopts the concept of humanization, protects the top device of the dust collector, and facilitates personnel maintenance, use and management.

9) All steel materials of the dust collector are mechanically shot blasted before and after processing.

For more information about the production and installation of DMC pulse bag filter, please call Yongming Machinery for free consultation. The company's professional engineers are looking forward to your inquiry.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机