Tel: +86 17310763143

E-mail: sales@nmgymjx.com

Website: www.nmgymjx.com

Address:The intersection of G242 and 311 roads, Langshan town, Linhe district, Inner Mongolia, China.

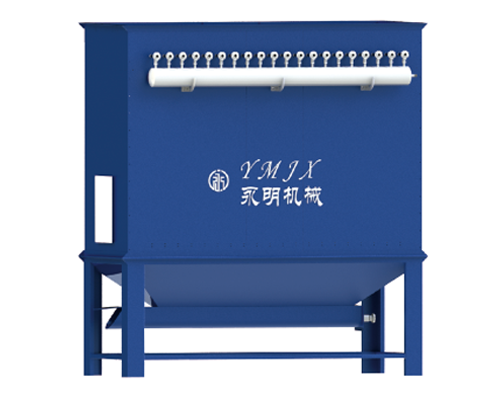

DMC series large-scale spray pulse long bag filter is based on the company's pulsed dust removal technology, combined with advanced dust removal technology at home and abroad. A pulse long bag dust collector developed to meet the needs of high air volume flue gas purification. It combines the advantages of two types of chamber backflushing and pulse cleaning, and overcomes the shortcomings of insufficient backflushing strength and general pulse cleaning and adsorption, so that the cleaning efficiency is improved and the blowing frequency is greatly reduced.

The product uses a submerged pulse valve, which reduces the pressure of the blowing air source and the energy consumption of the equipment, prolongs the service life of the filter bag and the pulse valve, and greatly improves the comprehensive technical performance. It is widely used in the purification of normal temperature or high temperature dust-containing gas such as building materials, metallurgy, petrochemical, grain, steel, carbon black, electric waste incineration industrial furnaces and the recovery of powdery materials.

Performance characteristics:

1. Adopt pulse jet cleaning technology, strong cleaning ability, high dust removal efficiency, low emission concentration, low air leakage rate, low energy consumption, low steel consumption, small land occupation, stable and reliable operation and good economic benefits. It is suitable for flue gas dedusting in metallurgy, building materials, machinery, chemical, electric power, light industry and other industries.

2. The cabinet adopts airtight design, good sealing performance, excellent sealing material for inspection door, kerosene leak detection during production, and low air leakage rate.

3. The inlet and outlet air ducts are compactly arranged and the airflow resistance is small.

4, using the chamber to stop the wind pulse spray cleaning, long cleaning cycle, low consumption, can double the life of the filter bag and valve.

5, can achieve non-stop bag change, maintenance does not affect the normal operation of the equipment.

6. The upper bagging method is adopted to improve the maintenance operation environment.

Reprint statement:

The article is reproduced on the Internet for the purpose of transmitting more information and does not imply endorsement of its views or verification of the authenticity of its content. If the reprinted works infringe the author's right to authorize, or have other damages such

De-impurity

Delivery of the wind for raw material

Dmс-160 type pulsed jet cloth filter

Grading screen

Polisher

De-stoner

Unbroken elevator

KTF4-3000 Sunflower seed hulling & separating machine

Ident cylinder sunflower seed cleaning machine

Product introduction of cyclone dust separator

Vertical hoist

Gravity separator

5XF-2000 type compound screening machine

KTF3-1200 Sunflower seed hulling & separating machine

KTF4-2800型葵花脱壳分选机